Medallion provides update on process development projects

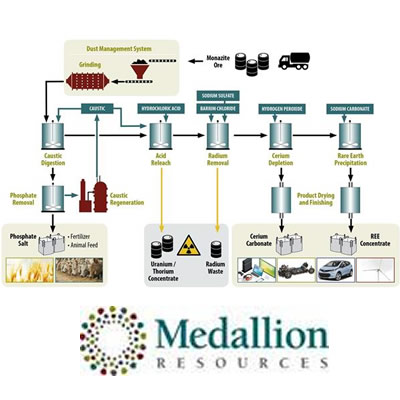

A current top-level process flow diagram of monazite sand. — Photo courtesy Medallion Resources Ltd. Medallion Resources Ltd. (TSX-V: MDL; OTCPK: M

A current top-level process flow diagram of monazite sand. — Photo courtesy Medallion Resources Ltd.

Medallion Resources Ltd. (TSX-V: MDL; OTCPK: MLLOF; Frankfurt: MRDN) – “Medallion” or the “Company”), pursuing smart production of magnet metals, today provides an update on its process development work now in progress at the Saskatchewan Research Council (SRC) and the Chemical Engineering & Applied Chemistry Department at the University of Toronto.

“These current projects will answer key questions about our waste stream and process optimization work and move us much closer to a formal economic study,” said Kurt Forrester, PhD, Medallion’s metallurgist. “We are entering into discussions with engineering groups on a study to determine capital and operating costs for our proposed monazite rare-earth processing plant.”

- To optimize the Company’s approach to the safe and economical management of waste materials, the SRC is analysing waste streams produced from additional “crack and leach” testwork on monazite sand feedstock. Following completion of this work, the findings and samples will be shared with waste processors and disposal firms for review and guidance.

- To streamline process design, researchers at the University of Toronto’s Chemical Engineering & Applied Chemistry Department are generating solubility data to establish precise thermodynamic models of the phosphate conversion and caustic regeneration projects. The Company expects this work to potentially provide significant cost savings during plant operations.

“The timing of this work coincides nicely with the market interest we’re seeing in rare-earth magnet metals and in our NdPr-rich concentrate,” said Don Lay, President & CEO of Medallion. “With our recent capital raise we can move more quickly to evaluate potential plant sites in North America and work with feedstock suppliers to ensure timing and quality of monazite feedstock.”

Medallion is preparing for near-term production of rare-earth magnet materials in North America through the processing of by-product monazite sand—in a modern, clean, and automated process. Monazite sand is rich in rare-earth elements neodymium and praseodymium (also known as “NdPr”) which are critical input for lightweight and powerful rare-earth magnets. Rare-earth magnets are essential to Automotive and Robotics (electric motors), Defense (Missile Guidance Systems), and Clean Energy (Wind Turbines) industries. Given the dominance of China as a rare-earth producer and tense global trade relations, automakers and other industry groups are seeking non-China sources to meet increasing demands for NdPr. Medallion is committed to following best practices and accepted international standards in all aspects of mineral transportation, processing and safe management of waste materials. More about Medallion (TSX-V: MDL; OTCPK: MLLOF; Frankfurt: MRDN) can be found at medallionresources.com.

Forward Looking Statements Apply