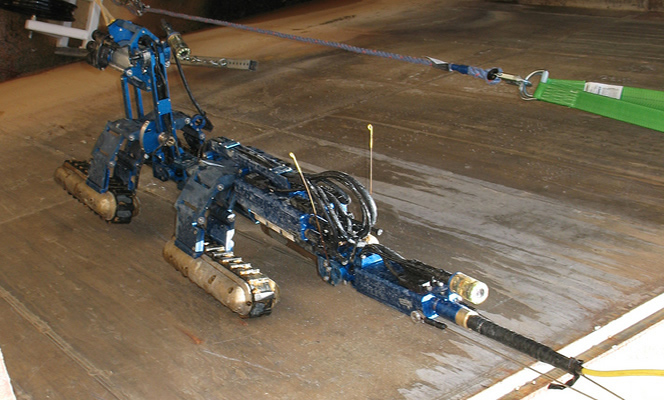

Rugged mining robots can go where no man has gone before

1 of 2Inuktun’s Versatrax 300 being lowered into the Climax Mine in Colorado, September 2009. — Photo courtesy Inuktun Services2 of 2Inuktun’s Versatr

1 of 2Inuktun’s Versatrax 300 being lowered into the Climax Mine in Colorado, September 2009. — Photo courtesy Inuktun Services

2 of 2Inuktun’s Versatrax 300 at the entrance to an unknown mine, June 2010. — Photo courtesy Inuktun Services

Colin Ross is a mild-mannered sort of guy who’s only too eager to tell you about the products his company creates. But think of those products as toys for even a millisecond and you’ll soon see a different side of him emerge.

“Nothing upsets me more than when someone calls these a toy,” said Ross. “These are finely crafted, purposeful, rugged vehicles that can carry out specific inspections. They can be used to save lives or they can be used to increase the output of your business. They are not toys.”

As marketing director for Inuktun Services Ltd. (ISL), founded in 1989 and located in Nanaimo, B.C., Ross said the devices his company designs and manufactures are far from playthings. They are remotely operated vehicles (ROVs) and modular robotic systems designed for use in confined spaces and hazardous environments. They are rugged systems that he said are perfectly suited to working in the mining industry.

Some of Inuktun’s bigger projects include the creation of a long range inspection crawler that traversed through copper slurry pipes at the Escondida mine in Chile, the creation of a robot that could travel through a 6-inch borehole and which sold to a number of US exploration operators, and a custom robot that was built to search for survivors during the Crandall Canyon Mine Collapse in 2007.

From visualization of boreholes deep below the ground to inspection of flooded mines without the need to first pump out the water, the number of applications where robots can be of service in mining and exploration are literally limitless, Ross said. Inuktun can customize and retrofit their systems to offer solutions to whatever problems their clients are faced with, as they did recently for a company in Quebec.

“We had a customer come to us from a mine in Quebec asking, ‘Can you make a camera that would fit into this seven-eighth diameter hole and can you go 1,000 feet?’ ” said Ross. “Before this we had only gone as far as 1000 feet, so we went back to the board and designed a new driver board that could go to 1,700 feet. Now we have a standard product and a standard drop camera system that will go to great lengths.”

The areas where Ross sees robotic systems being of best service is where there is a question of human safety or less than appealing environments, where there is a need to get an assessment done for cheaper than it would cost to get a human in there, or where there is a need to collect useful data that can help a company make critical decisions.

“We started with ‘We can’t send a person into that part of the mine, maybe we can send a robot in there,’ ” said Ross. “But now can we can take it further. Now we have systems that can get purposeful information, to see a scan of the structure, to see if there are any cracks in the rock. Now we are able to extract information to help the people that are operating the mine operate in a safer environment.”

And while industries like oil and gas, nuclear, and hydro-electric have begun to embrace these new technologies, Ross said percentage-wise it’s been difficult to gain that same level of acceptance in the mining industry.

As to why that is, Ross is unsure, but he has a number of theories.

“It’s partly about changing the mindset and the culture of trusting in the technology,” said Ross. “Robots today are still in the realm of sci-fi in many people’s minds and not seen as the practical pieces of equipment they are that can save a company time, money and possibly lives.”

Ross also theorizes that many management groups are simply stuck in their well-trodden ways.

“If they are used to doing things one way, it often takes a change in management to implement new processes and new ways of doing things. I work in a technology-based company so we’re changing all the time, but many companies feel overwhelmed by the amount of change that is happening and feel that if this is the way they’ve always done it, why change?”

Still another possibility, concedes Ross, is the steep price tag that come with utilizing this level of specialized technology.To combat that, Inuktun now offers companies the option of either renting or leasing their systems rather than having to invest in the equipment themselves for the long haul.

“Nobody wants to own anything anymore,” said Ross. “So our response has been to work toward more rental and lease options. You may not be able to afford to buy a $200,000 robot, but you can rent it for $9000 a week, or lease it over a 48-month period. We’ve been seeing more and more as that being a way we can bring this technology to companies who work on operating budgets rather than large capital budgets.”

Gradually, said Ross, through financing options and better educating of the industry itself, Inuktun and other robotic companies are slowly starting to see their Canadian markets grow, including in the auxiliary support side of mining where they’re seeing new additional uses for their systems.

“I was out in Saskatchewan last week,” said Ross. “And I told a geologist if he wants to do seismic work or he wants a system to go and plant explosives for blasting, we can be the ones that can provide him with that remote operation and we have systems that can do that delivery. And he said, ‘Oh, I never thought of it like that.’ “

For those types of “aha” moments to occur on a more regular basis, Ross believes it might first take, unfortunately, either a tragedy where an individual is injured or killed doing a job that could easily be handled through automation, or a change in a company’s staffing to people with backgrounds in automation who will look at how the company is doing things and simply say, “This is silly. Why are we using manual processes when we can cut down our delivery time and we can cut down our scheduling if we just switch over to a robotic system.”

Until that day comes, Ross said he’ll continue to educate companies and by continue to offer up solutions to those who do buy into the products that his company sells. Until then, he’ll also continue to get offended whenever someone looks at his systems and tries to dismiss them as mere toys.

As Canada’s resource industries begin to adopt new levels of automation through remotely operated vehicles (ROVs) and unmanned vehicles systems (UVS), the companies that provide such technology are equally ramping up their efforts to take full advantage of this emerging market.

“Customer demand is growing,” saId Dewar Donnithorne-Tait, president and CEO of Canada’s Centre for Unmanned Vehicles Systems (CCUVS). “So our focus is shifting to where we are application-rich, and where we have jurisdictional need and advantage. That is primarily in the resources sector, the environmental concerns associated with the resource sector, and efficient management of municipal services and utilities.”

“Natural resources, mining, surveying, oil and gas, energy, all of them stand to benefit handsomely from the proper implementation and adoption of unmanned technology,” said Matt Rendall of Clearpath Robotics, located in Waterloo, Ontario. “Especially in Canada, because of how vast the country is. It’s just a matter of when and who. The industry is going to go that way, but will it be a Canadian company that takes them there or will it be another country or another company that’s going to generate all that economic stimulus for someone else?”